ASTHRA

IN-SITU HAND DRIVEN ID CLAMPING FLANGE FACER

We, at Shenoy Engg. PVT. 株式会社. manufacture In-situ, portable Electro-Mechanical Flange facers. These flange facers are mainly used in for generating smooth or serrated finish on the flange butting surface. We have supplied these flange facers to various companies and they are performing to the customer’s satisfaction.

Based on the feed back from the users of our electro-mechanical flange facers, there is a need for a flange facer which should be compact and light weight. It should be easily to carry and power source required for operation should be easily available.

We took all these factors into consideration and developed a Hand Driven Flange Facer. 70% of the flange facer is made of aluminum which make it light and is hand driven which eliminates the need for any power source, be it electricity, hydraulics or pneumatic. Since this does not involve any powered source except for human power, this product is fire hazard free and most ideally suited for petroleum, chemical refineries.

This flange facer has a facing range from 25 mm to 310mm i.e. 1” to 12” and has a clamping range of 1” to 6”. The main components of this facer like arm, housing, is cast from Aluminum to make it light. This whole unit weighs under 8 Kgs. Sliding surface is made of LM guides and blocks to provide utmost frictionless smooth movement, keeping in mind the operator’s fatigue. The tool is moved over the LM guides through a leadscrew-box nut arrangement coupled through a worm reduction gear box. The input of the worm reduction gear box has a knob which can be rotated. The box nut is made of phosphorus bronze which creates less friction against the lead screw while rotating. The tool is provided with a single point cutting tool of cross section 10×10 ミリメートル. The flange facer will be provided with tool holder have standard ISO carbide inserts, which are easily available in the market. The arm on which the slide unit is mounted is connected to rotatable housing. A case hardened hollow spindle is supported by two deep groove ball bearings inside the housing to provide sufficient stiffness against the radial cutting loads while facing. Inside the hollow spindle, a threaded clamp shaft is provided. The spindle also has 3 slots, where 3 jibs can be mounted. When the clamp shaft is rotated, a taper provided on the shaft pushes the jibs out of the slot equally thereby clamping the facer inside the bore and self-centers the Flange Facers.

| Specification: | Inches | Millimeter |

| Facing Range | 1” to 12” | 25.4 mm – 304.8 ミリメートル |

| Clamping Range | 1” to 6” | 25.4 mm – 152.4mm |

| Tool Vertical Traverse | 1” Manual through fine pitch bolt | 25.4 mm Manual through fine pitch bolt |

| Tool Post Swivel | ±45° | |

| Tool | Single point cutting tool with indeaxble Standard Carbide inserts | |

| Maximum Depth of cut | 0.2 mm or 0.007” | |

| Finish Obtainable | Serrated Finish and smooth finish by changing of gear box. | |

| Slides ways | LM Guides of HIWIN make | |

| Gearings | 2 No.s of SKF make deep groove ball bearings. | |

| ドライブ | Hand Driven through worm reduction gear box coupled to lead screw and phosphorus bronze box nut | |

| Clamping | By self-centering jibs – Through tightening of threaded clamp shaft | |

| Jibs | Detachable jibs given in incremental sizes. Held to each other through screw | |

| Jib locking in Spindle | Through O-rings | |

| Targeted Market | Piping, refinery, ship building, maintenance work | |

ビデオ:

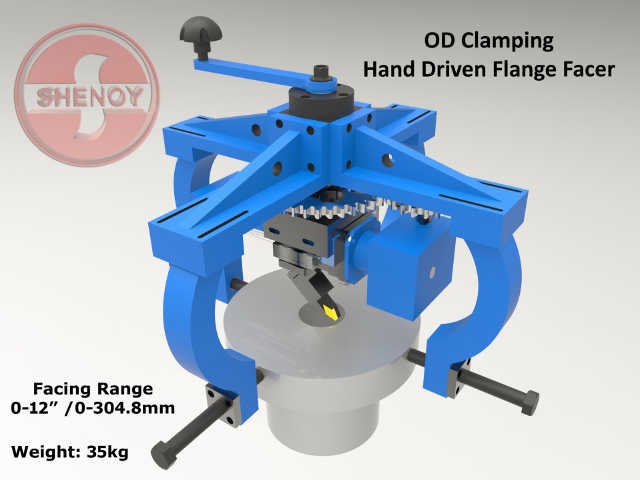

IN-SITU HAND DRIVEN OD CLAMPING FLANGE FACER

| Specification:Inches | Millimeter | |

| Facing Range | 0 to 12” | 0 mm – 304.8 ミリメートル |

| Clamping Range | 3” to 12” | 76.2 mm – 304.8 ミリメートル |

| Tool Vertical Traverse | 1” manual through fine pitch bolt | 25.4 mm manual through fine pitch bolt |

| Tool Post Swivel | ±45° | |

| Tool | Single point cutting tool with indeaxble Standard Carbide inserts | |

| Maximum Depth of cut | 0.2 mm or 0.007” | |

| Finish Obtainable | Serrated finish and smooth finish by changing of worm reduction gear box. | |

| Slides ways | LM Guides of HIWIN make | |

| Bearings | 4 No.s of FAG make deep groove ball bearings. | |

| ドライブ | Hand Driven through spur gear combination with worm reduction gear box coupled to lead screw and phosphorus bronze box nut | |

| Clamping | Through tightening of threaded studs | |

| Leveling | Manually through M16 threaded bolts provided on the legs of the facer | |

| Weight | Approximately 35 kg | |

If you are interested, please feel to contact us.

Contact:

Shenoyエング. PVT. 株式会社.

#7, 16th Cross, Doddanna工業団地

Near Peenya 2nd Stage, バンガロール – 560 091

インド

Ph: +91-80-2836 1767; +91-80-2836 1725

Website: www.shenoyengineering.com

メール: info@shenoyengineering.com

製品情報についてはお問い合わせください

連絡先の詳細

- +91-80-28361767

- info@shenoyengineering.com

- +91-80-28361725

製品

- ツール & カッター

- フライススペシャライゼーション

- 特殊工作機械

- 金属切削SPM

- 特殊工作機械

- 8 Station Rotary table based Drilling and Chamfering SPM

- 四頭ヘッドミーリングSPM

- 2ステーション4主軸旋削SPM

- CNC 3 軸4スピンドルプロファイルミリングSPM

- テーパーミーリングSPM

- トリプルスピンドルタッピングSPM

- U掘削とボーリングSPM

- Drilling, SPMの面取りとバリ取り

- Con Rod Taper Milling SPM

- Con Rod Small End Bore Chamfering SPM

- Rotary In-Gate Milling SPM

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- Table Top Drilling Machine with Servo Positioning

- Double Head Slot Milling & Notch Milling SPM

- Double Head Slot Milling & Drilling SPM

- 二重フライス盤 - エコノミー版,,en,ロータリーインゲートミリングSPM,,en,AXES,,en,CNCポータブルミリング,,en,スレッドマシン,,en,軸CNCフライス盤,,en

- 2 軸CNC MutliテーパーターニングSPM

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- Quadruple Head Slot Milling & Slitting SPM

- デュプレックスプランジフェーシングSPM

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Rotary Coordinate Drilling SPM

- 銃掘削機

- CNC BORING MILL- VMC, HMCとVTLは1つにロールバック

- スーパーは、特殊工作機械の仕上げ

- 特別な目的のマシンをバフ

- 製作SPM

- 金属切削SPM

- その場スペシャ

- CNCマシン

- 予算垂直マシニングセンター

- 3 Axes CNC Milling Machine

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- CNC Double Column Milling Machine

- CNC 3 軸4スピンドルプロファイルミリングSPM

- ポータブル 2 軸CNC旋盤

- 3 Axes Horizontal CNC machine

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- 2 軸CNC MutliテーパーターニングSPM

- CNCプラノミラーズ

- CNCの特別な目的の溶接機

- Fixtures for VMC and HMC

- 添付ファイル

- Services

に翻訳 :-

翻訳を編集