Welding Automations and Welding Fixtures

We have designed and developed many welding fixtures, especially for Automobile industries mainly for sheet metal components, which are vulnerable to thermal distortions during welding.

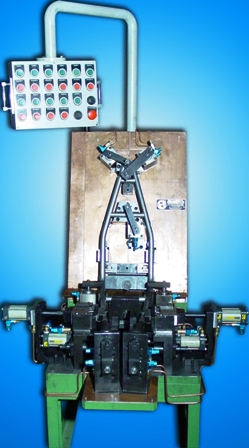

STYLING BRACKET WELDING FIXTURE FOR TWO WHEELER COMPONENT

DOWN TUBE WELDING FIXTURE OF A MOTORBIKE FRAME

We have designed and manufactured many Welding Automations

ROTO-LINEAR WELDING SPM

- Hydraulic cylinder for job clamping & de-clamping.

- AC servo driven rotary table for providing required angle in linear welding on both sides of the component & semi-circle rotary movement in the end.

- Hydraulically operated linear movement for the torch on LH & RH sides of the component.

- Forward movement & home position retraction of the welding torch through hydraulic movement.

- Touch screen enable HMI (human machine interface) for the servo motor to facilitate quick changes in the angle setting & program edit.

- PLC for an efficient auto-cycle.

- LM guideways or hardened guideway strips for all linear sliding surfaces.

- Machine guard & copper sheet protection from welding spatters.

Job Description:

As shown in the above inset image, the component is unassembled halves which when assembled, resembles “Ice-candy shape”. In engineering terms the component starts off as a trapezoidal prism which ends with a curve instead of a flat.

Construction:

A rigid fabricated base on which a rotary table, driven by a servo motor is mounted. On the rotary table a job clamping fixture is mounted. Adjacent to the rotary table, a compound slide with hydraulically actuated motion is mounted. The cross axis movement of the compound slide, moves the welding torch to the pre-set required position. The longitudinal axis of the compound slide is for providing linear movement to the welding torch. A hydraulically operated clamping cylinder clamps & de-clamps the job automatically & quickly.

Working:

Place the bottom half of the job on the fixture & place the top half on it. Press auto-cycle button; Vertical hydraulic cylinder clamps the job. Welding torch approaches the welding zone of the job in its cross verse traverse. As the welding commences at the one end, linear movement slide carries the welding torch as it welds the top & bottom half till the point of beginning of the arc. Now the linear movement of the torch stops & the servo enable rotary table keeps feeding the job for semi circle welding. On sensing the end of the arc, PLC again stops the rotary movement of the table & the linear welding on the other side of the job takes place. On completing the welding, the fully welded two halves of the job get de-clamped and the machine is ready for the next job. The servo drive of the rotary table facilitates variable angle setting in linear welding and also in semi-circle welding. Total time required from clamping till de-clamping is about 30 seconds.

MULTI PORT CIRCULAR WELDING SPM

A typical automobile fuel tank has a number of ports for inlet, outlet, fuel level indication, drain etc. We have developed an automatic multi-port welding SPM, which welds the ports to the fuel tank in a single setting. A well design fixture ensures accurate positioning, clamping rigidity and buckling-resistance effects, forced by the welding heat and clamping pressure. Multiple linear slide movements, assisted by an efficient PLC programming, provide accurate location to the welding torch to commence welding of each port to the tank in rapid succession. Rotary movement, in-built in the main fixture, provides smooth & accurate circular movement to the component at the exact locations. This is an ideal, low cost solution for medium volume component industries, engaged in the manufacture of sheet metal components, like fuel tanks, silencer etc.

LEAK TESTING MACHINES

This leak testing machine is developed on a rotating giant wheel principle, which accommodates multiple components to be leak tested to the machine. It also helps to minimize the mess generated by the conventional leak testing machines by splashing of leak testing liquid. On rotating wheel, 4 fuel tanks are mounted. As one fuel tank gets immersed in the liquid for identifying the leaking welding joint, previously tested tank is to be removed from the wheel and a new tank is to be mounted. Like this, there is a provision for mounting 4 tanks in the wheel. The tank, wheel and other vital parts of the machine are made of stainless steel.

CNC WELDING SPECIAL PURPOSE MACHINE

We offer wide range of welding solutions like Welding Rotators, Welding Positioners, Column & Boom Manipulators, welding Automation systems, welding manipulators etc. A Welding SPM consists of A Welding Fixture for accurately locating the components and for firmly holding & clamping the components in the required position. The locating dimensions are machined in a jig boring machine and clamping elements consists of U or V blocks, hold-down elements, locating pins, bushes etc. The fixture is designed for accurate location of the components repeated and consistently. The automatic clamp and de-clamp mechanism is generally through pneumatically operated cylinders. Depending upon the welding requirements of the components that are to be welded, the fixture may hold the components in a fixed position or a rotating mechanism can be provided. Linear slides, carrying the welding torches, is the essence of the welding SPM.

In this CNC welding SPM, there are 6 welding torches, simultaneously welding both the end-flanges to a square tube in 20 seconds. The rapid approach of the torches to the welding zone, actual welding and rapid retraction of the welding torches through suitably designed slides are through servo motors and drives. Servo drive ensures accurate movement repeatedly and helps maneuvering the feed rates as per the requirement. The linear slides consist of LM guideways, ball lead screws and box nuts for a smooth & friction free movement.

Electrical system consists of servo motors and drives for the linear movements of the torches, which obey the commands from the combination of PLC & limit switches. Electrical system is well designed for an efficient auto-cycle of all linear movements and also job ejection through ejection cylinders after welding and retraction of the slides to the home positions. To take care of varying lengths of job, VFD controlled length adjustment mechanism is provided. A user-friendly HMI helps the operator to on-machining program editing easily and in a very short time.

Except loading and unloading of the jobs, complete welding sequence, including job ejection after welding are fully automatic. Automatic welding machines produce good and uniform quality of welding consistently without being effected by any of the adverse factors of manual welding like fatigue, human error etc. Automated welding solution can boost up the productivity as much as 20 times.

VIDEO :-

Contact us for product information

Contact Details

- +91-80-28361767

- info@shenoyengineering.com

- +91-80-28361725

Product

- Tools & Cutters

- Milling Specialization

- Plate Edge Milling, Plate Bevelling Machine

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Plano Miller, Duplex, Floor Type

- Milling Head with Facing attachment

- Multi Angle Universal Milling Attachment

- Right Angle Milling Attachments

- Converted Plano Millers

- Planomilling Conversion Kit

- Special Purpose Plano Miller

- Ram Type Milling & Boring Head

- Milling Retrofits

- 3 Axes Special Purpose Milling Machine

- Mutli Head Milling SPM

- Milling Heads and Milling Head Attachments

- Special Purpose Machine

- Metal Cutting SPM

- Special Purpose Machine

- 8 Station Rotary table based Drilling and Chamfering SPM

- Quadruple Head Milling SPM

- Two Station Four Spindle Turning SPM

- CNC 3 axes four spindle Profile Milling SPM

- Taper Milling SPM

- Triple Spindle Tapping SPM

- U Drilling and Boring SPM

- Drilling, Chamfering and Deburring SPM

- Con Rod Taper Milling SPM

- Con Rod Small End Bore Chamfering SPM

- Rotary In-Gate Milling SPM

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- Table Top Drilling Machine with Servo Positioning

- Double Head Slot Milling & Notch Milling SPM

- Double Head Slot Milling & Drilling SPM

- Duplex Milling Machine – Economy Version

- 2 axes CNC Mutli Taper Turning SPM

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- Quadruple Head Slot Milling & Slitting SPM

- Duplex Plunge Facing SPM

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Rotary Coordinate Drilling SPM

- Gun Drilling Machine

- CNC BORING MILL- VMC, HMC and VTL rolled into one

- Super Finishing Special Purpose Machine

- Buffing Special Purpose Machine

- Fabrication SPM

- Metal Cutting SPM

- Insitu Specialization

- Portable CNC Mill

- In-Situ Flange Facer, Portable Radial Planer & Semi Insitu Solution

- 3 AXES, CNC PORTABLE MILLING & THREADING MACHINE

- Portable 2 axes CNC wheel turning lathe

- ASTHRA – Hand driven flange facer

- Semi Insitu Solutions

- Square Flange In-Situ Miller

- Flange Miller

- Line Boring Special Purpose Machine

- CNC Machines

- Budget Vertical Machining Center

- 3 Axes CNC Milling Machine

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- CNC Double Column Milling Machine

- CNC 3 axes four spindle Profile Milling SPM

- Portable 2 axes CNC wheel turning lathe

- 3 Axes Horizontal CNC machine

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- 2 axes CNC Mutli Taper Turning SPM

- CNC Plano Millers

- CNC Special Purpose Welding Machine

- Fixtures for VMC and HMC

- Attachments

- Services