Special Purpose Machine

SPECIAL PURPOSE MACHINE OR SPECIALLY DESIGNED MACHINE

SPMs offer tremendous scope for high volume production at low investment and at low cost of production when compared to CNC machines. SPM is a high productivity machine, with specially designed tooling and fixture, dedicated for mass producing the same component day in and day out. A judicious combination of limit switches, sensors, logic controls, automatic job clamping etc is the essence of a SPM. A well conceived SPM finds ways and means to utilise the man and machine to the optimum. We offer low cost dedicated SPMs for mass production of small components of 2 & 4 wheelers, tractors, trucks, engines etc. Typical components are rear wheel flange, shifter cam, shifter fork, clutch sleeve etc. OUR SPMs ARE SUITABLE FOR MASS PRODUCTION OF COMPONENTS WHICH INVOLVE OPERATIONS LIKE TURNING, BORING, FACING, DRILLING, REAMING, TAPING, CHAMFERING ETC. These machines work with 4 to 8 stations, depending upon job requirements. Most of the machine concept is standardized which enables very fast delivery of the machine. Please send us your enquiry with the following details for enabling us to send you our offer:

(a) Job drg

(b) Job material

(c) Operations to be carried out on the job to be clearly indicated in the drg

(d) Desired rate of production

(e) Precondition of the job as presented to the machine

MULTI SPINDLE, HIGH SPEED MILLING MACHINE

- 4 spindle units – two vertical & 2 horizontal

- Hydraulically operated 4 slide units for linear movement

- Hydraulically operated automatic job clamping system

- Auto-cycle through of limit switches & PLC

- Ideal for mass production

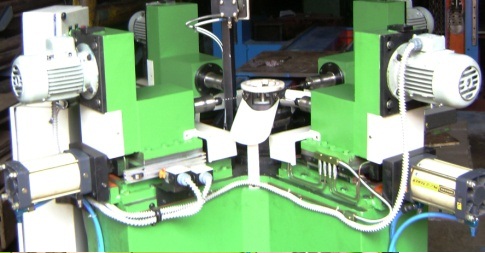

Duplex Milling Machine

We offer custom-built Duplex Milling Machines to end face multiple components, both from the front and from the back simultaneously. Hydraulically operated automatic clamping system, with a well designed job holding fixture, facilitates multiple components to get clamped simultaneously and quickly. Two milling heads, one in the front and the other in the back, simultaneously perform end facing operations on both the faces of all the mounted components simultaneously in one rapid go. Job clamping, rapid approach of the spindle, machining, rapid homing, rapid de-clamping etc will the part of an efficient auto-cycle, delivered by the combination of limit switches and PLC. The total cycle time for duplex end facing the multiple components, is a few seconds. The machine is designed for high productivity at low cost, consistent accuracy and with least dependency on the operator’s skill.

SEPL’s milling heads are already well known for reliability and ruggedness in thousands of Plano milling conversions all over India and abroad. Matched pair angular contact bearings, used for supporting the spindles of unit heads of milling SPMs, ensure a very high level of spindle accuracy and high spindle speeds.

Combination of turcite and case-hardened guideways for high wear resistance and smooth liner movement, automatic lubrication system, efficient coolant and chip disposal system, machine enclosure, easily accessible machine controls etc are the features of the Duplex Milling Machines. Automatic chip disposal system is offered optioally.

Multi Station Pendulum Milling SPM

This multi station pendulum type of milling SPM is another effort by us to utilize the man and the machine to the optimum. What otherwise would have been possible for at least 2 SPMs (each SPM with 2 spindle units) and two different operators, is made possible by this single Pendulum Milling SPM in terms of productivity. The Pendulum SPM consists of totally 3 spindle units and two job holding fixtures at LH & RH stations. When the machining is going on at both the ends of the same component simultaneously in LH station, another job is being loaded in the RH station. This SPM has a capacity of producing 150 finished components per hour. For this kind of output, 3 machining centers would have been needed, which means the additional space, power & operator for 2 more machines.

Side Frame Milling SPM

This is a Side Frame Milling SPM. The SPM has totally 9 axes and 3 spindle units, thus providing a unique capability to machine the different segments of the same component simultaneously in the same setting. It avoids machining the same component in multiple setting and considerably saves on time and boosts productivity and accuracy.

Video Presentation of the Side Frame Milling SPM:-

Other SPM’s that we have Built :-

Knurling SPM

A spinning kurnling wheel, when pressed on a component, produces knurls.

Knurled OD adds to the grip on a cylindrical male OD of a component when a female cylindrical component tries to grip it. Handle bars in a two wheeler or bicycle is the ideal example for this application. Instead of conventinal lathes, dedicated SPMs for knurling helps mass produciton of knurled components in thousands.

Knurled OD adds to the grip on a cylindrical male OD of a component when a female cylindrical component tries to grip it. Handle bars in a two wheeler or bicycle is the ideal example for this application. Instead of conventional lathes, dedicated SPMs for knurling helps mass production of knurled 2 wheeler handle bars and other components in thousands.

- Two HSS knurling wheels mounted on hydraulically operated slide units

- A well designed job holding fixture with quick clamping and de-clamping mechanism through clamping cylinders

- Hardened and ground male guideway strips; Turcite linings for female sliding surfaces; Wipers for guideway protection

- Metallic, collapsible guideway covers

- A well designed coolant and chip disposal system (without a chip conveyor)

- Automatic lubrication system

- PLC based auto-cycle for automatic clamping of job, knurling operation and de-clamping of job

- A compatible & operator-friendly electrical panel and console which will be easy and simple to maintain – complete with all required interlocking logics and safety features.

Along with your enquiry, kindly send your component drawing for enabling us to send you a techno-commercial offer.

Product

- Tools & Cutters

- Milling Specialization

- Plate Edge Milling, Plate Bevelling Machine

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Plano Miller, Duplex, Floor Type

- Milling Head with Facing attachment

- Multi Angle Universal Milling Attachment

- Right Angle Milling Attachments

- Converted Plano Millers

- Planomilling Conversion Kit

- Special Purpose Plano Miller

- Ram Type Milling & Boring Head

- Milling Retrofits

- 3 Axes Special Purpose Milling Machine

- Mutli Head Milling SPM

- Milling Heads and Milling Head Attachments

- Special Purpose Machine

- Metal Cutting SPM

- Special Purpose Machine

- 8 Station Rotary table based Drilling and Chamfering SPM

- Quadruple Head Milling SPM

- Two Station Four Spindle Turning SPM

- CNC 3 axes four spindle Profile Milling SPM

- Taper Milling SPM

- Triple Spindle Tapping SPM

- U Drilling and Boring SPM

- Drilling, Chamfering and Deburring SPM

- Con Rod Taper Milling SPM

- Con Rod Small End Bore Chamfering SPM

- Rotary In-Gate Milling SPM

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- Table Top Drilling Machine with Servo Positioning

- Double Head Slot Milling & Notch Milling SPM

- Double Head Slot Milling & Drilling SPM

- Duplex Milling Machine – Economy Version

- 2 axes CNC Mutli Taper Turning SPM

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- Quadruple Head Slot Milling & Slitting SPM

- Duplex Plunge Facing SPM

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Rotary Coordinate Drilling SPM

- Gun Drilling Machine

- CNC BORING MILL- VMC, HMC and VTL rolled into one

- Super Finishing Special Purpose Machine

- Buffing Special Purpose Machine

- Fabrication SPM

- Metal Cutting SPM

- Insitu Specialization

- Portable CNC Mill

- In-Situ Flange Facer, Portable Radial Planer & Semi Insitu Solution

- 3 AXES, CNC PORTABLE MILLING & THREADING MACHINE

- Portable 2 axes CNC wheel turning lathe

- ASTHRA – Hand driven flange facer

- Semi Insitu Solutions

- Square Flange In-Situ Miller

- Flange Miller

- Line Boring Special Purpose Machine

- CNC Machines

- Budget Vertical Machining Center

- 3 Axes CNC Milling Machine

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- CNC Double Column Milling Machine

- CNC 3 axes four spindle Profile Milling SPM

- Portable 2 axes CNC wheel turning lathe

- 3 Axes Horizontal CNC machine

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- 2 axes CNC Mutli Taper Turning SPM

- CNC Plano Millers

- CNC Special Purpose Welding Machine

- Fixtures for VMC and HMC

- Attachments

- Services