In-Situ Flange Facer, Portable Radial Planer & Semi Insitu Solution

Flange Facer is a multi-utility machine and it can also be used for doing other machining operations like drilling, boring, thread cutting etc by adding a self-powered unit head and using proper tooling and axes synchronization.

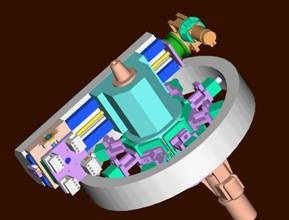

Flange Facer consists of a rotary drive unit and clamping arms. Power cables from the rotary table are routed through an imported brushless rotary joint connector with an universal joint which permits the flange facer to do the operation in vertical, horizontal and in any angular position without the danger of cables getting entwined with rotating parts.

The rotary drive unit consists of a pair of pre-loaded, extra heavy duty taper roller bearings, located in an accurately dimensioned, forged alloy steel body. The rotary drive is through a gear box and a motor. A vector VFD provides step less rotational speeds. The main body and the cross axis ram are made of high grade CI casting, heavily ribbed and stress-relieved. The box type ram is quite unique in design, perfectly balanced, light in weight, robust in construction to withstand the deflection. The cross feed drive is through a worm reduction gear box & VFD controlled motor. Proper balancing and additional care in design ensure smooth cutting even when the cutting takes place in the extreme end of the ram. The rotational drive and feed axis are synchronized through a PLC. Adjustable feed end limit switches are provided for the ram movement.

The 100 mm vertical stroke is for setting the depth of cut and generally this is manually operated. It is possible to offer self-feed drive for the vertical axis and synchronize it with the cross axis movement & rotary movement through a PLC.

For a quote, kindly furnish the following details:

a) maximum and minimum diameter of your flanges.

b) Whether your jobs are vertical or horizontal resting c) Whether you prefer OD or ID clamping type flange facer.

We have developed ID (manual) clamping type flange facer for the facing range Ø210 to Ø600 mm, available in stock. For clamping, we have used a 4 jaw self-centering chuck, which offers a very rigid clamping.

A video link is provided in the bottom of this webpage.

Advantages of Electro-Mechanical Flange Facers over Pneumatic or Hydraulic Flange Facer

- Cables from control panel to the Flange facer are routed through an imported brushless rotary joint, to avoid entanglement of cables, while in a Pneumatic or Hydraulic Flange Facer is Leak-prone due hydraulic or pneumatic lines & joints.

- Electro-Mechanical Flange Facers are very portable as it needs only a electric power supply to run, where as Hydraulic or Pneumatic Flange Facers have limited portability, since the flange facer needs either compressed air or hydraulic power, which in turn, again need power supply.

- Our Electro-Mechanical Flange Facers use pre-loaded, extra heavy duty taper roller bearings for effective cutting on large over-hang in full torque. Cutting performance of pneumatic or hydraulic flange facer fluctuates, depending upon the line pressure.

- The cross feed system is through rack & pinion or lead screw box mechanism, which is driven through a worm reduction gear box & controlled by a VFD.

- Manual Vertical stoke upto 100mm for setting depth of cut through micro meter type graduated collar

- Powered self feed for operations like boring & facing

- ±45? tilting of tool post for taper machining.

- Axial & radial run out compensation

- Highly affordable, indigenously developed, short manufacturing lead time & virtually maintenance-free

- Custom-built to suit to your application without the need to go for either too large or too small flange facer.

DIA 3.2 meters flange facer for Godrej (Plant 15), video of this Machine :

The flange facer, supplied to Mazagaon Docks Ltd is for small diameter of, say dia 1.2 mtrs.Video presentation is shown below:

e>

Recently we have supplied 2 flange facers to M/s Geecy Engg Pvt Ltd, New Bombay. You may kindly click on the. The video is shown below:

Flange Facer- ID Clamping type, using a 4 jaw self centering chuck, we offer ID clamping type flange facer for a minimum clamping range of 300mm to a maximum clamping range of 1000mm.

A Flange Facer of facing dia range of 1500mm to 2500mm. This Flange Facer is able to remove 2.5mm of steel in one pass.

ASTHRA

-In-Situ Hand Driven Flange Face by Shenoy Engg. Pvt. Ltd.

Contact us for product information

Contact Details

- +91-80-28361767

- info@shenoyengineering.com

- +91-80-28361725

Product

- Tools & Cutters

- Milling Specialization

- Plate Edge Milling, Plate Bevelling Machine

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Plano Miller, Duplex, Floor Type

- Milling Head with Facing attachment

- Multi Angle Universal Milling Attachment

- Right Angle Milling Attachments

- Converted Plano Millers

- Planomilling Conversion Kit

- Special Purpose Plano Miller

- Ram Type Milling & Boring Head

- Milling Retrofits

- 3 Axes Special Purpose Milling Machine

- Mutli Head Milling SPM

- Milling Heads and Milling Head Attachments

- Special Purpose Machine

- Metal Cutting SPM

- Special Purpose Machine

- 8 Station Rotary table based Drilling and Chamfering SPM

- Quadruple Head Milling SPM

- Two Station Four Spindle Turning SPM

- CNC 3 axes four spindle Profile Milling SPM

- Taper Milling SPM

- Triple Spindle Tapping SPM

- U Drilling and Boring SPM

- Drilling, Chamfering and Deburring SPM

- Con Rod Taper Milling SPM

- Con Rod Small End Bore Chamfering SPM

- Rotary In-Gate Milling SPM

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- Table Top Drilling Machine with Servo Positioning

- Double Head Slot Milling & Notch Milling SPM

- Double Head Slot Milling & Drilling SPM

- Duplex Milling Machine – Economy Version

- 2 axes CNC Mutli Taper Turning SPM

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- Quadruple Head Slot Milling & Slitting SPM

- Duplex Plunge Facing SPM

- H BEAM, I BEAM MILLING, DRILLING & TAPPING MACHINE

- Rotary Coordinate Drilling SPM

- Gun Drilling Machine

- CNC BORING MILL- VMC, HMC and VTL rolled into one

- Super Finishing Special Purpose Machine

- Buffing Special Purpose Machine

- Fabrication SPM

- Metal Cutting SPM

- Insitu Specialization

- Portable CNC Mill

- In-Situ Flange Facer, Portable Radial Planer & Semi Insitu Solution

- 3 AXES, CNC PORTABLE MILLING & THREADING MACHINE

- Portable 2 axes CNC wheel turning lathe

- ASTHRA – Hand driven flange facer

- Semi Insitu Solutions

- Square Flange In-Situ Miller

- Flange Miller

- Line Boring Special Purpose Machine

- CNC Machines

- Budget Vertical Machining Center

- 3 Axes CNC Milling Machine

- 3 Axes, CNC, ID Trepanning, OD Turning & End Threading SPM

- CNC Double Column Milling Machine

- CNC 3 axes four spindle Profile Milling SPM

- Portable 2 axes CNC wheel turning lathe

- 3 Axes Horizontal CNC machine

- Twin Station 8 Axes CNC Controlled Rough Turning SPM

- 2 axes CNC Mutli Taper Turning SPM

- CNC Plano Millers

- CNC Special Purpose Welding Machine

- Fixtures for VMC and HMC

- Attachments

- Services